Header image credit: YAGO_MEDIA

One of the most important parts of design is the make. Whether I’m at the beginning at the process or the end, I have to make something to be able to visualize and make my concepts and ideas tangible. While computer screens and applications can do a great job, not every deliverable is meant to exist solely on a screen, and sometimes it can be a hindrance.

By printing on paper, I can get a new perspective on what it is I am producing and push my process further, and when it comes to printed deliverables, everything about that paper is all the more important.

How does paper happen?

Currently, there are many methods and materials that can be used to produce what we would call “paper,” but they all take a pretty similar format.

Pulp

Whether you use wood, cotton, or any other type of fiber from a plant, that material is mixed with water to create a squishy substance called pulp. This substance is what is turned into paper sheets and controls many attributes of the paper, such as:

- Texture

- Opacity

- Ink absorbancy

- Whiteness

Processing

To turn the pulp into the paper we’re familiar with, it is spread thin, dried, and then put on rollers that dry, stretch, and thin the paper even more. This process can also be paired with something called finishing, which involves putting the paper through metal rollers called calenders, which can be soft and dull, hard and shiny, or other mixes of characteristics that add special qualities to the paper for specific uses.

Large sheets of paper are going through the first round of the process, being stretched, dried, and thinned to become complete sheets of paper.

Image credit: Piedmont Plastics

Types of Paper

Coated

Image credit: Alexnld.com

In order to better control how things print on the page, some papers are coated with a special coating that restricts how the ink is absorbed into the paper. This can reduce bleeding of the ink and create sharper content. Such qualities lend it to be used to print images, book covers, brochures, and other media that requires high fidelity prints. Within coated paper, there are a couple types that all achieve specific results.

- Cast coated paper has a mirror-like glossy texture. It is typically more reflective than glossy paper, which most people think of when it comes to coated paper

- Gloss paper is the most common coated paper, and is typically used for printing images (earning it the moniker of “photo paper”).

- Dull/silk paper is a sort of middle ground between gloss and matte. It has a non gloss surface for a solid ink lay and readability.

- Matte paper is the least reflective coated paper with a softer texture than the rest. It has the best readability of the four.

Offset and Opaque

Image credit: House of Vinyl

Offset and opaque papers are the more commonplace type of paper and are used for a wide variety of tasks because of their wide range in weights and opacities. Because of their wide array of uses, they are typically sold in bulk to mass produce the products.

- Offset paper was developed to be used with offset printing, which transfers ink from a plate to a rubber blanket, which then transfers it to the paper. This paper is the typical choice for most printers.

- Opaque paper is lighter, which allows for a slight translucence. Their lighter weight also makes them very economical when it comes to mailing.

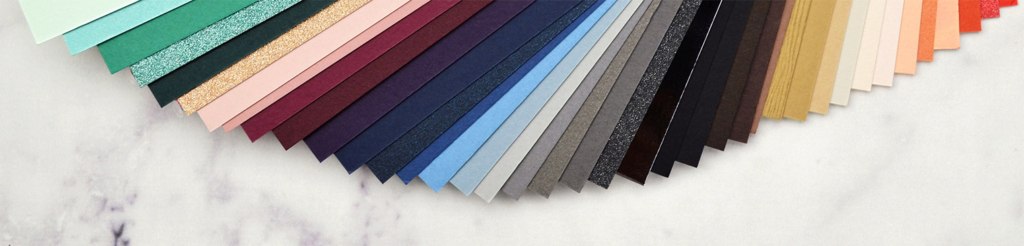

Text and Cover

Image credit: Cards and Pockets

Cover papers are the stand-in for hardcovers and therefore will have a heavy weight. Typically paired with lighter weight papers, called text papers, their heavy weight makes them perfect to act as a protective binding for the interior content. Like other papers, specialty versions of cover paper can be ordered with different fiber makeups and colors. Because of their use as the outer shell of documents and other paper artifacts, they are known to come with special textures called a finish. Some of these finishes include:

- Cockle is a finish commonly found in writing or bond papers that mimics handmade paper. It creates a rough and wavy texture through air drying and light tension.

- Eggshell is a subtle finish that mimics the surface of an egg shell.

- Felt finishes are known for their distinct soft texture that is commonly used for letterpressing, embossing, and foil stamping.

- A groove or vertical finish create linear patterns in the paper via an off-machine embossing process.

- An indicator of high-quality paper, a laid finish uses a “dandy roll” to create lines that run with the grain of the paper.

- Linen finishes create a fabric-like texture that is made by embossing with a patterned roll.

- A smooth finish, as the name suggests, aims to get paper as smooth as possible (determined by how many times it is calendered). Using a number called the Sheffield scale, the lower the number on the scale, the smoother the paper.

- Typically found on uncoated papers, a vellum finish is characterized as a more natural, uncalendered machine finish.

- Lastly, opposing the vellum finish, wove finishes are a standard machine finish with no pattern.

Writing

Image credit: Berkshire

When most people think of paper, they typically are thinking of writing papers. Referred to as bond papers historically, writing papers are commonly used for stationary systems in corporate settings. Since they operate as stationary systems, they can have watermarks on the paper. These can either be from the manufacturer, which can signify high quality if the manufacturer is well known.

Another common thing that writer paper is known for is having cotton mixed into the pulp. This creates a softer texture that makes the paper feel more high quality. However, the trend towards digital screens has make paper finishes and quality characteristics more visual than tactile.

Specialty

Image credit: WNY Book Arts

Specialty paper serves as the catch-all for the crazy and unique styles and production methods for paper. Some common specialty papers are patterned paper, metallic or pearlescent finishes, or unique production methods.

One important thing to remember with specialty papers is that can take longer to produce mass quantities of, so make sure you plan ahead!

Jargon of the Paper World

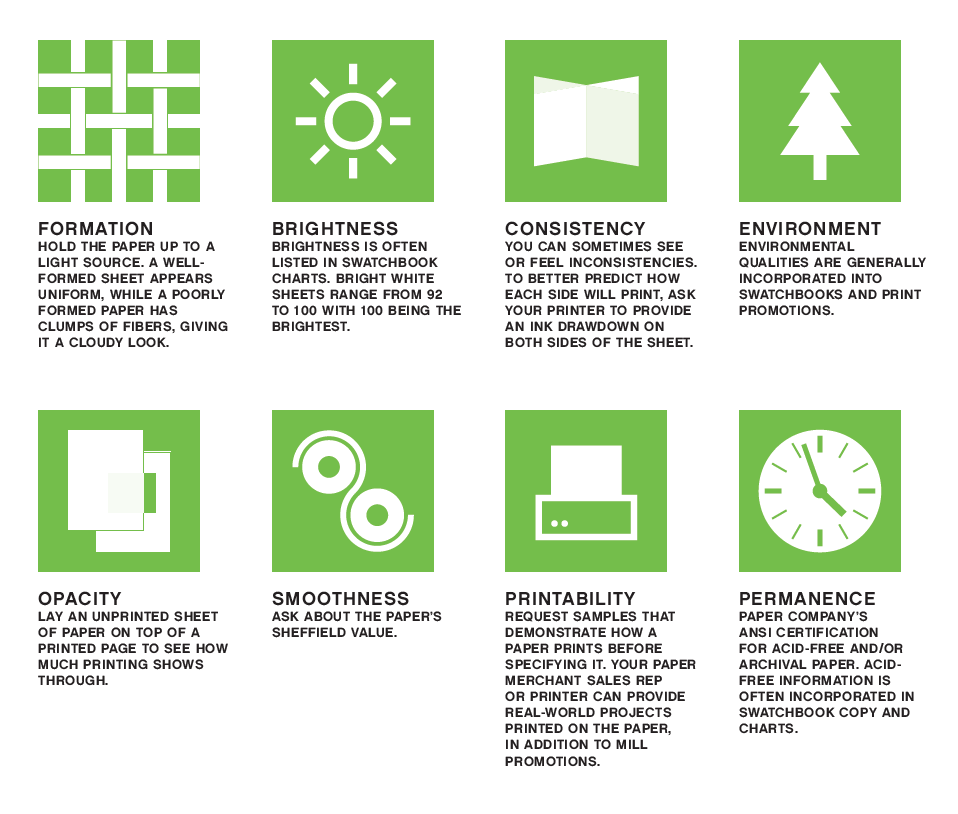

When it comes to talking paper, it’s important to know what qualities and characteristics those who truly know paper use to identify important differences and draw lines between different types of paper.

- When talking about paper fibers, one of the most important traits is formation, which refers to the uniformity and distribution of the fibers. A better formation will have a smooth and even ink absorption, whereas poor formation makes uneven ink absorption and looks spotty.

- Opacity is pretty self explanatory. Much like the digital counterpart, a 1% means maximum transparency whereas a 100% means completely opaque.

- Brightness refers more to the indirect brightness a paper generates based on how reflective it is. The higher the number, the more reflective and the brighter the paper is.

- Finish or smoothness can affect how ink reacts to the paper, so measuring this trait is important in order to predict how things printed on the paper will react. This uses the Sheffield scale mentioned earlier.

- Side-to-side consistency refers to the process paper goes through when it is made. The wire side, which touches the wires on the paper machine, and the felt side, which doesn’t. The smaller the difference between these two sides, the better the paper because of their ability to print similarly on both sides.

- Printability is a bundling of using some of the traits mentioned earlier, like opacity, finish, and formation, to determine how well things print on the paper.

- Outside of the actual manufacture of the paper, environmental qualities, which refers to the ethical and sustainable sourcing of materials, can affect the usage of certain papers that chose not to follow common practices of sustainable paper production.

- In addition to environmental qualities, paper permanence also deals with traits outside of the manufacture of the paper and deals with the longevity of the paper. Things such as degradation and tearing are other important things to consider about paper.

Image credit: Mohawk, “Paper Basics”

Paper on a Scale

While normally I try to avoid the scale when the word weight gets mentioned, it’s not the same with paper. Paper weights (not to be confused with a paperweight) refer to a combination of the thickness of the paper and the actual weight, where a heavier weight means a stockier piece of paper. Much like general paper characteristics, the paper enthusiasts have their own terms they use.

- A caliper is the actual measured width of the paper in thousands of an inch, since paper is incredibly thin. This can either take the form of a decimal like 0.001 in or 1 point. This value is a summation of something called a basis weight and the paper’s finish.

- The basis weight, despite what I mentioned earlier, is the actual weight of 500 sheets of a specific paper’s basic size. This helps provide a standard system that ignores the quality and size of the paper sheets being measured. In addition, 2 times the basis weight, or the weight of 1,000 sheets of that paper’s basic size, is called the m weight.

- GSM (Grams per Meter Squared) is the universal measurement used for paper weights.

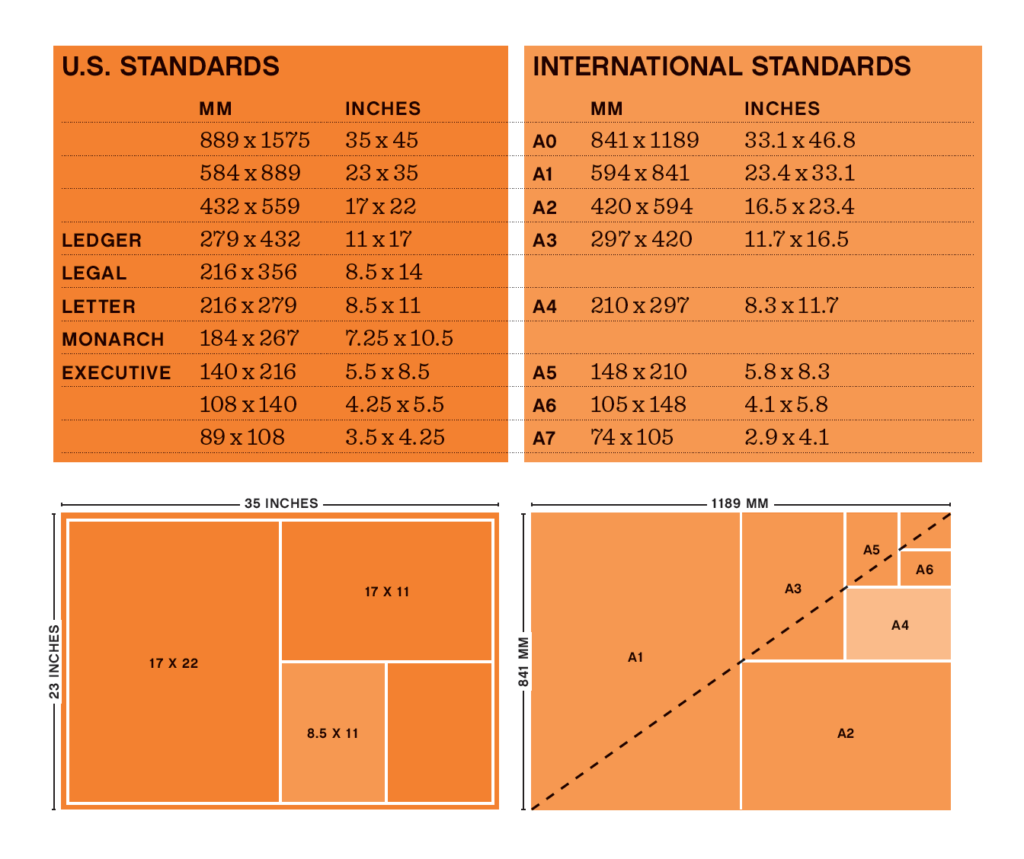

How big can it get?

Another wonderful thing about paper is it comes in many different sizes. The most common one is letter, since it is the most widely available and used size of paper, but there are still so many paper sizes used for stationary systems, large scale printed media, and so much more.

Image credit: Mohawk, “Paper Basics”

When it comes to paper, there are often so many things I need to consider that it can be overwhelming. However, my task as a designer is to make educated decisions. By doing the research and going through the design process, it is always possible to narrow down your options to the truly correct fit for your needs. Plus, it’s always good to have a library of information in your arsenal like this.

References

Mohawk. “Paper Basics.” 2015. PDF file.

“Paper characteristics.” IBM, https://www.ibm.com/docs/en/i/7.4?topic=management-paper-characteristics

“The Ultimate Guide to the Different Types of Paper for Printing.” B&B Press, https://www.bbpress.co.uk/news/the-ultimate-guide-to-the-different-types-of-paper-for-printing